Drilling

Drilling machines are built for fast, high-precision hole processing across all panel surfaces, essential for cabinet assembly and modular furniture. Whether single-side or six-side, Excitech’s drilling solutions reduce manual labor, speed up production, and ensure perfect alignment every time. Designed for MFC, MDF, and plywood, they’re a core part of efficient panel processing lines.

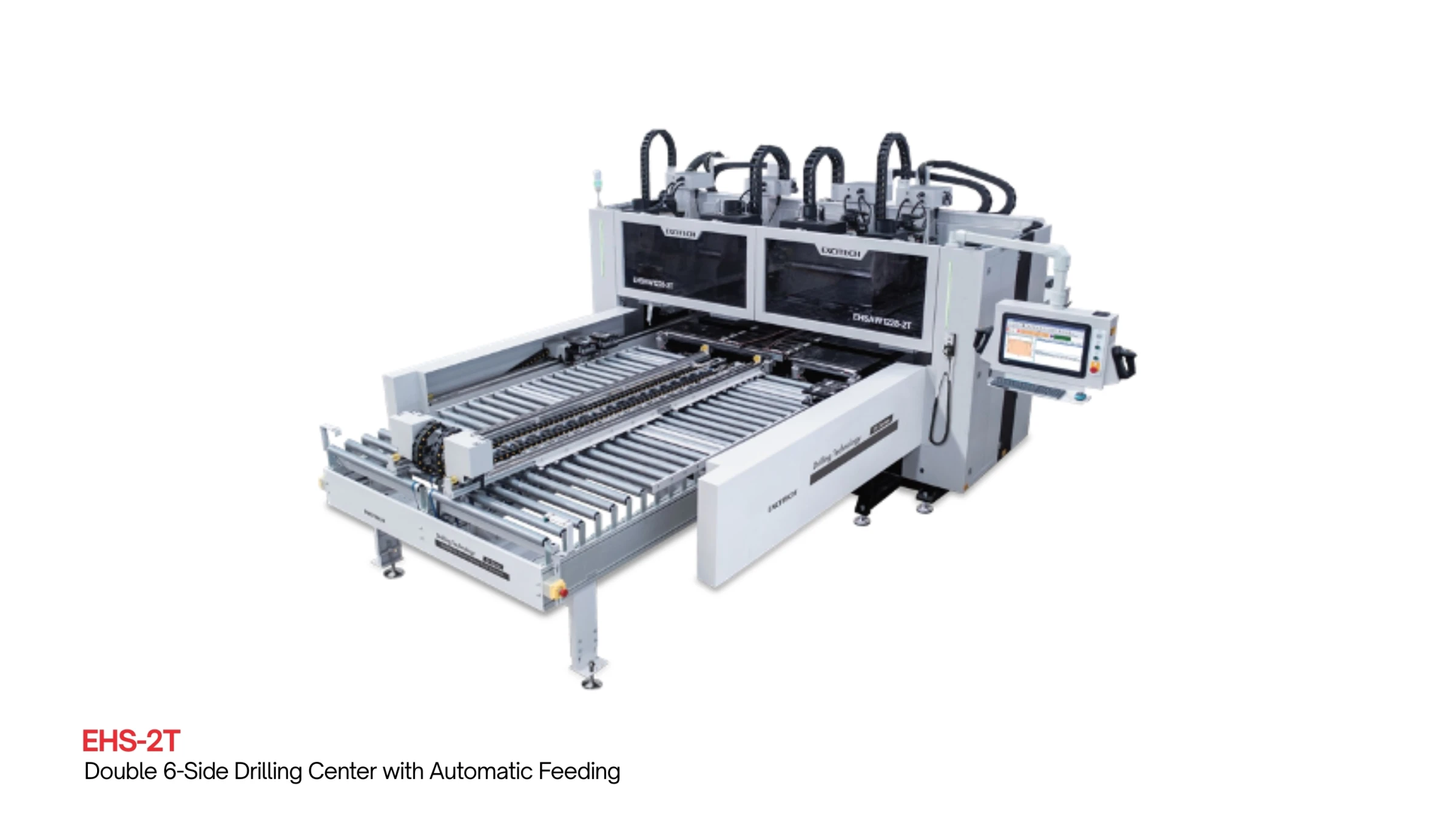

EHS-2T Double 6-Side Drilling Center with Automatic feeding

High-efficiency 6-side drilling center equipped with an automatic feeding system for continuous, unattended production. Built for speed, accuracy, and volume, it processes MFC, MDF, and plywood panels with minimal operator input.

- Full 6-side drilling and grooving with auto infeed

- CNC control with automatic tool changers

- Conveyor-style loading for uninterrupted cycles

- Ideal for large-scale, high-throughput production lines

Suitable for modular furniture, flat-pack systems, cabinets, wardrobes, and continuous drilling of MFC, MDF, and plywood panels.

EHS-2T Double 6-Side Drilling Center

High-efficiency machine that drills all six sides of a panel in one pass. Built for precision and speed, it's ideal for MFC, MDF, and plywood furniture components.

- Full 6-side drilling and grooving in one cycle.

- CNC control with automatic tool changers.

- High-speed spindle system.

- Great for mid- to high-volume production

Suitable for Modular furniture, cabinets and wardrobes, and MFC, MDF, and plywood panel drilling.

6-Side CNC Drilling Machine

Precision CNC drilling solution capable of processing all six panel sides in one setup. Designed for accuracy and flexibility, it suits a wide range of furniture components using MFC, MDF, and plywood.

- Simultaneous drilling on top, bottom, front, back, left, and right

- CNC-controlled for exact hole placement

- Compact structure for space-saving integration

- Efficient for batch or custom production

Suitable for panel furniture, wardrobes, cabinets, and drilled components made from MFC, MDF, and plywood.

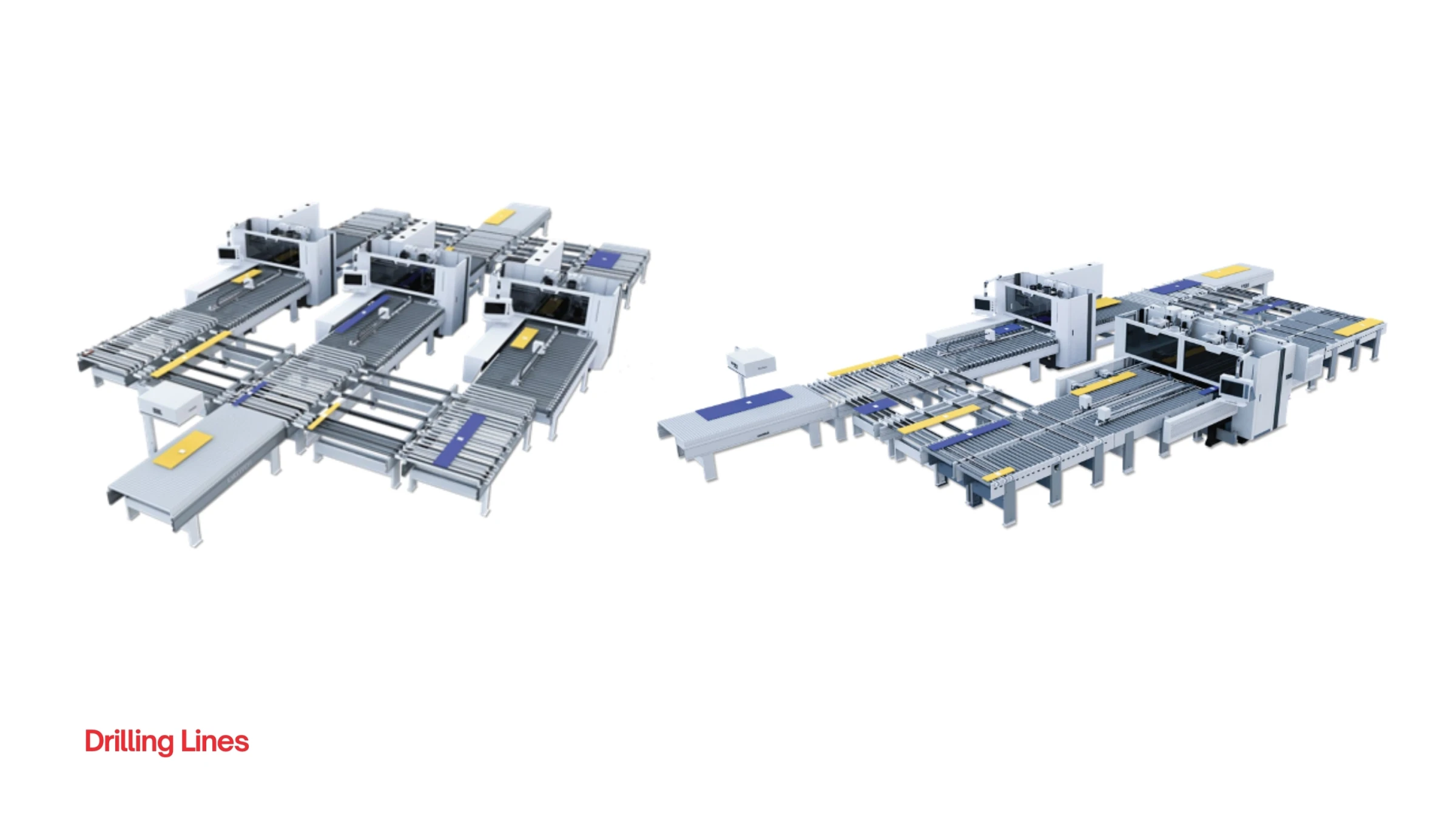

Drilling Lines

Fully automated multi-station system designed for continuous high-speed drilling of furniture panels. Combines precision, volume, and minimal labor in one integrated production flow.

- Multi-station drilling with synchronized conveyors

- Automated loading, drilling, and transfer between units

- CNC control across all stations for exact hole positioning

- High-speed spindles and optional tool changers

- Customizable layout for different production flows

Suitable for MFC, MDF, and plywood panels used in large-scale cabinet, wardrobe, and modular furniture production lines.

Ideal for:

- MFC, MDF, plywood panels

- Cabinets, wardrobes, modular furniture

- Dowels, hinges, and shelf pin drilling

- Flat-packs, and ready-to-assemble components